Table of contents!

- Accounting code?

- Override code?

- Average order quantity?

- Product field?

- Safety stock plan flag?

- Physical inventory tags?

- Price breaks?

- Minimum and multiple?

- Repetitive scrap?

- Material pull?

- FTP file transfer?

- Kanban labels?

- Pallet sheets?

- Receiving label?

- Shop order traveler?

- Labor tracking break and lunch adjustments?

- Floor stock?

- Knowing where the cost comes from?

- What are Low Level Codes (LLC)?

- Total selling cost?

- Stocking time?

Accounting code?

The default accounting code is "A" but can be changed in System

Manager/Configuration Editor/Shipping Address. The accounting code

associated with each part number can be set to different values

(i.e. B, C, D etc) then assign different GL #'s based on the

accounting code. Example: In FG (user defined) stockroom you can

have three different product lines and desire to keep each product

line associated with different GL #'s. Assume we have 25 parts in

product line 1, 25 parts for line 2 and 25 for line 3. All 25 parts

in product line 1 could have an accounting type of "A", all 25 parts

in line 2 could have accounting code "B" and line 3 could be "C".

In the Financial module/Maintain GL Accounts/Stockrooms -- You would

set up three entries for:

"FG" stockroom with accounting type "A" associated with the desired

GL# for line 1 products.

"FG" stockroom with accounting type "B" for another GL# for line 2

products.

"FG" stockroom with accounting type "C" for another GL# for line 3

products.

The Maintain Default GL Acct Tables must also be setup for for each

different accounting code even if the GL #'s are the same. i.e. If

you are using 3 different accounting codes then each default code

must have 3 entries. One for "A", one for "B" and one for "C". In

the same Financial module/Maintain GL Accounts/Default - For

Accounts Payable you would set up three entries for:

ACCTPAY with accounting type "A" associated with the desired GL# for each part with an accounting code of "A"

ACCTPAY with accounting type "B"

ACCTPAY with accounting type "C"

The from-to charge report and FIM module will generate errors if

every accounting type code is not represented in the default table

or stockroom associated with the part!

Another way to handle the different GL#'s is to have all parts as accounting type "A" and have different "FG" stockrooms. i.e. "FG001" for one product line and "FG002" for another. That way there is only 1 entry (for the "A" code) in the stockroom and default tables.

Back to Top

Override code?

The override GL account table provides the user the ability to specify a special GL account number be used when receiving or issuing material. The 3-digit override codes are set up in the Financial module/Maintain GL Accounts/Overrides. When receiving or issuing material the system offers the ability to specify an override code. If no code is entered the system will automatically apply the transaction to the GL number assigned to the default code.This capability permits the user to track material usage for a special project. i.e. If a special development project is launched the accounting department can assign a special GL # to track all cost associated with the project. The MRP coordinator simply assign a 3-digit GL Acct. override code with the special GL #. When issuing or receiving material the operator simply enters the override code in the GL Reference field when processing the transaction. The system does have a switch to force override codes for unplanned receipts.

Back to Top

Average order quantity?

The average order quantity is used for manufactured parts that have setup time to spread the setup cost over the "Average order size". If you have a minimum order quantity then the "average" should be set to at lease the minimum quantity. I.e. If the average order size is 30 pieces and the setup time is 30 minutes, the system will apply 1 minute's setup cost to each piece. The "audit part master" report in the Crystal Reports off-the-shelf audit group will check for average quantities.Back to Top

Product field?

This is a 4 digit field in part/sales that can be used to further sort category fields. This can be useful with generating a sales price list and additional sorting is desired on the category field.Back to Top

Safety stock plan flag?

In System Manager - Activity - System Configuration - Max Switches - MRP Plan Safety Stock. This is an option to plan safety stock orders if there is no demand for the part. If the inventory level is below safety stock and the flag is "N" the system will not generate a planned order to cover the shortage until there is a customer order or higher level demand for the part. If the flag is "Y" the system will generate a planned order anytime the inventory level is below the safety stock level.Back to Top

Physical inventory tags?

This option permits the user to build the Physical Inventory tag file ahead of time, pre-print the tags during daylight hours then just before starting the counting process automatically load the current on-hand quantities into the tag file.Additional sort -- If Crystal Report Writer is used to print the old style physical tags there is advantages over printing in MAX. The primary advantage is providing additional sorting capability. I.e. If you have a lot of parts in a stockroom and the location field is not used then specific items in the part master (commodity code) or other fields could be used to further sort the tags.

Back to Top

Price breaks?

You should have at least one price break even if the vendor does not give breaks. i.e. If the part is always $10.00 then enter a quantity of 1 with a cost of $10.00. If there is a price break then the minimum quantity should be reviewed.Back to Top

Minimum and multiple?

If the vendor does give a price break then consider setting the minimum order quantity to match one of the quantity breaks. i.e. If the vendor gives a break for 25 then consider setting the minimum order quantity to at least 25. Also, if you must purchase items in multiples then setup the multiple order quantity. i.e. If eggs are purchased, the minimum order quantity would be at least 12 and the multiple order quantity would also be 12. If the system needs 14 eggs the system would generate an order signal for 24 eggs! The Safety Stock and Inventory Evaluation report in the off-the-shelf Inventory Group can help determine average monthly usage based on history.Back to Top

Repetitive scrap?

We have set up a work-around in MAX to provide shift and reason code information along with actual manufacturing date for items that are good or scrapped. The repetitive scrap reports are not available in the off-the-shelf section because the reason code is different for each user. We have done extensive work in generating Crystal report worksheets for the user to record actual production and scrap at the time of manufacture.Back to Top

Material pull?

We have set up a procedure in MAX to provide the ability to stock material in more than 1 stockroom and automatically signal a request when the stock level in the primary stockroom gets below a specified level. The system will also indicate the desired quantity to "pull" or transfer. This is useful when large amounts of material is received from off-shore suppliers and can not be stocked in the primary stockroom. Click here to visit our material pull reports.Back to Top

FTP file transfer?

The FTP (File Transfer Protocol) transfer function permits both Manufacturing Systems Group (MSG) and our customers to upload or download files of any size to a sub directory on our web site. This eliminated the problem of trying to attach large files to an email message. Click here to view our FTP transfer page.Back to Top

Kanban labels?

We have bar coded Kanban labels that can be used for bin's of material produced on the shop floor. Normally the kanban sheet is printed ahead of time and attached to the shop order. As material is produced and placed in bins one Kanban label is attached to each bin. This provides a simple and easy way to identify material produced on the shop floor and ready for the stockroom. Click here for an example of a 2-up Kanban label.Back to Top

Pallet sheets?

We have a bar coded pallet sheet that can be used when receiving pallets of material. The sheet is printed and placed on the pallet facing the fork lift driver. In addition to other items the sheet contains the part number, stock ID/location and quantity on the pallet.The fork lift driver can look at the sheet when placing the pallet in the warehouse. The sheet is also useful when performing physical inventories. If the pallet wrapping is not broken the counters can easily read the quantity on the pallet from 20 feet away. Click here for an example of a Pallet sheet.

Back to Top

Receiving labels?

We have a receiving label for purchased items that can be used to attach to material after receipt-to-stock. This label displays:- Part number and description

- Stock ID/location

- Part revision number

- Lot number

- PO #, date of receipt, vendor ID and unit of measure (Date on label helps FIFO procedure)

- Receipt-to-stock

- Print the label

- Attach the label to the material (Label on material indicates the PO has been received)

- Read the label to know where the material is stocked.

Back to Top

Shop order traveler?

The shop order traveler is used where a large number of shop order can be waiting at a work center. The traveler due date is converted to a large Julian date so the operator only needs to pick the lowest number traveler number to work on next. This is useful where a number of pallet's are waiting for work. The operator can easily see the "due date" from 10-20 feet away. Click here for an example of a shop order traveler.Back to Top

Labor tracking break and lunch time adjustments?

These reports will automatically calculate the adjustment time when an employee is logged in to the labor tracking system through or part of a morning break, lunch time or afternoon break. The employee can stay logged in to the labor tracking system and the system will automatically calculate the adjustment time. The gross run time, adjustment time and net run times are displayed. This provides management the best "actual" labor hours required to manufacture a part.Click here to go to the Labor Tracking Adjustment reports.

Back to Top

Floor stock?

Floor stock is usually used for very inexpensive parts (nuts, bolts and screws) that can be kept on the shop floor close by the assembly point. These items are reorder parts X-Y (usually Y for purchased). These parts do not appear on the pick list however, they are on the bill of material for costing purposes. The inventory crib keeps the stock of material. When the person on the shop floor needs material the crib person performs an unplanned issue from stock. This is usually a box of material. The MRP explosion will identify reorder parts below their preset reorder point. In between explosions either purchasing or inventory can run the "Below Reorder Point" report to identify parts that need attention.Click here for an example of the Below Reorder Point report.

Back to Top

Knowing where the cost comes from?

There is little known feature of the cost rollup module that permits the user to display a one page printout of the cost information without looking through pages of cost rollup printouts. This feature displays:- Material and material burden

- Labor and labor burden

- Routing labor by work center including setup cost

- Sub-contract cost, if any

- Enter part number

- Recalculate cost = Y but don't save

- Cost set = 00 if you have multiple cost option

- Report options in LLC sequence

- Rollup type = Neither (Be sure the rollup type is Neither)

- Process

You will notice the labor and labor burden cost on the top line are calculated in the routing section under the bill of materials. This is the labor cost for the top level assembly only. The routing cost also includes the setup cost calculated as a percentage based on the average order quantity. I.e. If the setup time is 30 minutes and the average order quantity is 30 then 1 minute is included in part routing operation under setup hours for that work center.

This report yields a nice one page report of all the cost associated with a part.

Back to Top

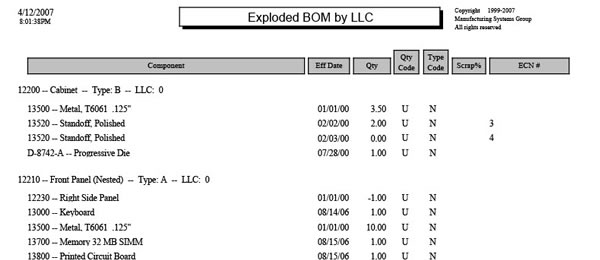

What are Low Level Codes?

Low level code (LLC) represents the lowest level a part occupies considering all bills of material. A part may be several levels deep in one bill and the same part report to the top level in another. When performing the low level code calculation the system determines the absolute lowest level for a part considering all bills of material. When the MRP explosion is run the system starts at LLC zero and determines the requirements for level 0 parts from customer or master schedule orders.After calculating the demands for level 0 parts the system moves to level 1 and calculates the component requirements from the demands on the level 0 part. For each demand for the parent part there will be demand times the BOM quantity for all components. This is called dependent demand. The total demand is established from the component dependent demand plus independent customer orders.

This procedure proceeds until all the levels have been processed. The total demand for a part is not known until the MRP explosion is processing the level associated with a part.

When parts are added to the system the LLC is zero until the LLC calculation is performed. If you run the explosion prior to performing the LLC calculation the system will not generate any requirements for the part unless it happened to be a top level part.

Several things to keep in mind about LLC's:

- Absolute vs. relative (The LLC on a part is not relative to it's current bill of material)

- Perform the LLC calculation prior to running the MRP explosion.

- Run the LLC calculation prior to recalculating cost rollups.

- Run the LLC calculation any time you add new parts to the part master.

- Perform the LLC calculation whenever adding to or changing the

product structure (BOM)

- Reset all low level codes (Performed when a lot of BOM's have been changed)

- Recalculate and no print

Example:

Top Level Part # (ABC

and it's components) (0) = low level code

^

^ 1st level down (456 sub-assembly and its components)

^

^

^

^ 2nd level down

sub-assembly

^

^

^

^

^ ^ 3rd level down

ABC(0)

123(1)

456(1) >>>>>>>456(1)

789(4)

222(2)

333(2)>>>>>>333(2)

444(2)

555(3)>>>>>>>555(3)

666(3)

888(4)

777(3)

789(4)

Notice that part 789 appears in two bill of materials however the lowest level the part "occupies" is level 4. The total requirements for part 789 are not known until the system is processing level 4 parts. There could be spare part orders or other demands for part 456, 333, 555 that could produce demands for it's components. There could also be spare part orders for 789.

Back to Top

Total selling cost?

There are three parts that make up the cost:

- Total Manufacturing Cost or Cost of Goods Sold

- Total Pricing cost and

- Total Selling cost

Total Manufacturing Cost (TMC) also called Cost of Goods Sold (COGS) is made up of the following:

-

Labor cost +

-

Labor overhead cost +

-

Material cost +

-

Material overhead cost

I.e. Labor$ + (Labor$ * LOH%) + Material$ + (Material$ * MOH%)

Example: If labor cost is $100, labor overhead is 300%

and material is $10, material overhead is 13%

Then COGS = $100 + $300 + $10 + $1.30 or $411.30

This is the cost to put the item “on the shelf”.Total Pricing Cost (TPC) is made up of:

-

Cost of goods sold above (COGS) +

-

Sales General and Administrative % (usually in 20-25% range)

TPC = COGS + SG&A%

$411.30 + ($411.30 * 23%)

Then TPC = $411.30 + $94.60 or $505.90

This is the companies break even cost!

Total Selling Price (TSP) is made up

of:

-

Total Pricing Cost +

-

Markup %

$505.90 + ($505.90 * 30%)

Then TSP = $505.90 + $151.77 or $657.67

Click here to view a Word document of total selling cost for later review.

Back to Top

Stocking time usually specifies the time spent in QC prior to moving the material into the inventory cage. This time is added to the plan and build time for either manufactured or purchased parts. If the company is purchasing material from off shore and the PO due date is to represent the supplier ship date simply increase the stock time to represent the working days it takes to get the product in the door after the international supplier ships from their dock. This time must represent the freight forwarder time, the number of days on the water, the receiving freight company time, travel days from the receiving freight company plus the incoming inspection days, if any. The vendor ship date will appear on the PO as the "Due date" however the MRP need date will be the "due date" plus the ship days. All days are working days. I.E. 21 days represent one calendar month.

Back to Top