Offshore Purchasing

Offshore Purchasing can provide a company the economic benefits of purchasing selected items from offshore manufacturing suppliers. This is not a simple task!

Several factors must be considered before undertaking this venture:

- Selection of potential products and supplier.

- Quality assurance process from offshore supplier.

- Training in the offshore purchasing process. This is a companywide education requirement.

- Lot size and container loading procedures.

- Offshore part marketing forecasting and report process.

- Lead times and scheduling reports.

- Freight forwarder and customs process.

- Type of bond selection.

- Inventory and safety tock levels to support 3 months delivery schedules.

- Inventory impact for receiving container quantities.

- Container tracking process.

- Container "Receiving" procedure.

- Documentation and procedures.

We are prepared to assist you in getting the Offshore Purchasing effort in place at your facility!

To start the process we will send two highly skilled, offshore experienced, manufacturing consultants to your facility for two days to audit the Offshore Purchasing potential at your facility. This audit will include:

- Purchasing department

- Minimum order quantities

- Inventory receiving department

- Inventory storage and the readiness for container quantities

- Inventory labeling process

- Container processing procedures and process

- "Pull-From" inventory locations and reports

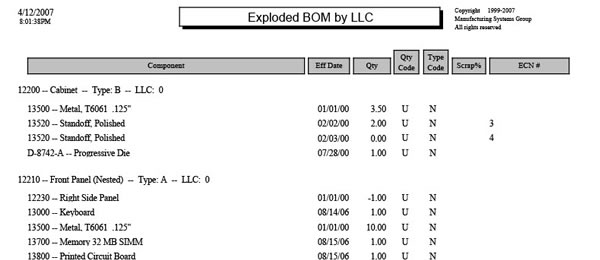

- Accountings and inventory stock cash requirements and product costing and benefits of offshore purchasing

- Marketing long range forecasting practices in place now

- Report requirements.

- Procedures and work instruction needs for this venture.

- Target parts for offshore purchasing.

On the afternoon of the 2nd day we sit down and review our findings and discuss our written recommendations.

Cost:

The price for the audit is $3,000 ($1500 per day) plus expenses. We arrive the night before to get an early start on the 1st day. All prices are in US dollars.

Click here to download a data sheet, in MS Word format, of this page for later review.

To inquire about Offshore Purchasing please contact us at:

Name: Roy Mapes

Phone: 727 642-4677

E-Mail: rmapes@mfgsysgroup.com